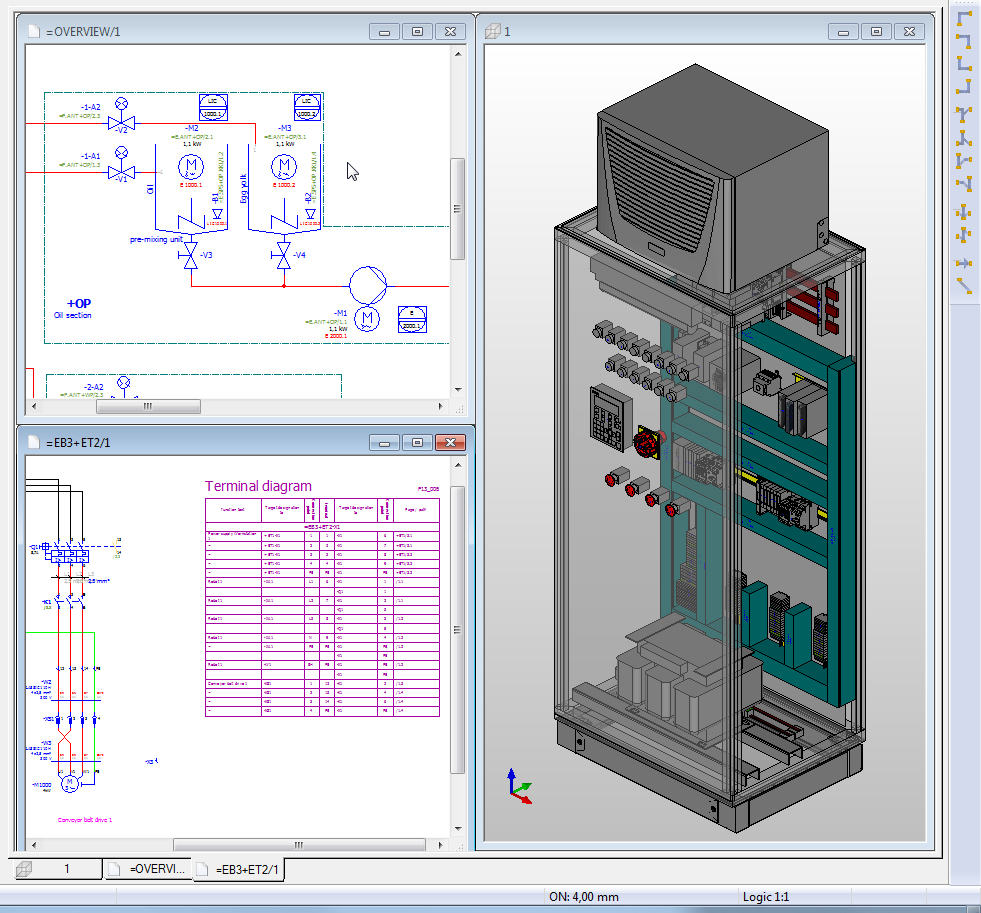

DEVELOPMENT OF PROJECT DOCUMENTATION OF ASUTP

Design work is entrusted to specialists who have the

necessary knowledge and experience in the design and implementation of

automated technological process control systems of any complexity in various

industries. Project documentation is performed in accordance with current norms

and normative documents of Ukraine. We have, in the company’s staff, a

certified design engineer in parts: ensuring operational safety, ensuring noise

protection and complying with fire safety requirements for construction objects

of the consequences (responsibility) class CC2 (medium consequences). Design

documentation is performed in AutoCAD Electrical and EPLAN automatic design

systems, and special highly specialized software of individual equipment

manufacturers, depending on the tasks. In addition to the main set of drawings,

project documentation is developed with additional sections, which are

necessary for software development, debugging and system maintenance in the

future.

SOFTWARE DEVELOPMENT

Main features: integrability, transparency and

reliability.

Software development includes:

● Implementation of logical control of mechanisms and processes during start-up, shutdown, normal (manual, semi-automatic and automatic) and emergency operation modes taking into account optimization of energy consumption, technology requirements and safety

● Configuration of industrial information networks of all levels and peripheral equipment of control systems

● Development of a complete set of top-level software for control systems (HMI, SCADA, MES, ERP)

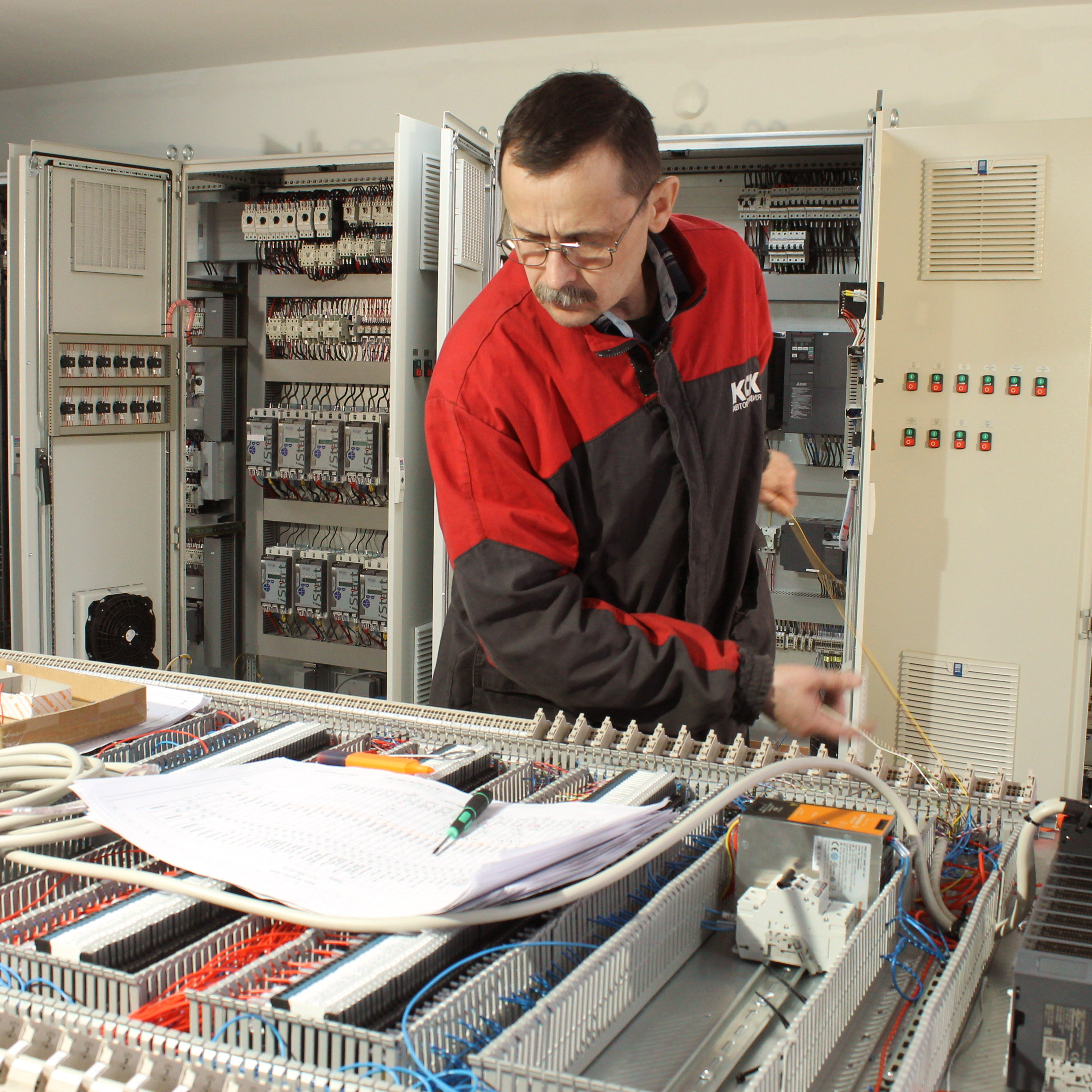

PRODUCTION OF ELECTRIC PANEL EQUIPMENT

The provision of complex solutions and services in the field of automation involves such a technological stage as the production of cabinets with electric power and electronic devices.

For this purpose, the structure of the «CSC – Automation» company has its own production facilities.

The production facilities of the «CSC – Automation» company consist of a production workshop in which control cabinets and power cabinets are assembled and tested, and mobile sets of equipment and tools that are used to carry out complex works on the territory of our Customers’ facilities.

ADJUSTMENT

The «CSC – Automation» company carries out commissioning and commissioning works in full, before the facility is put into operation. Organizational and engineering preparation of works includes:

● Formation of the optimal composition of the group, based on competence in certain directions

● Analysis of project documentation and documentation for individual devices

● Development of the work execution project, debugging methods and commissioning of individual elements

● Selection and completion of necessary measuring equipment, signal simulators, tools

Individual devices and system elements are subject to testing and debugging. The final stage is testing and determining the suitability of the automation system to ensure the operation of technological equipment. An important condition is the presence of the customer’s personnel during the work process. This will greatly facilitate the transition to system operation.

MAINTENANCE OF AUTOMATION SYSTEMS

We are developers of large complex systems that have been implemented in many enterprises. And, as a result, we have the experience, necessary knowledge and resources for quality maintenance of automation systems, compared to third-party organizations. This allows you to minimize the probability of errors during system maintenance and debugging. Directly by the specialists of the company «CSC -Automation» a full range of warranty and service maintenance work is performed:

● Scheduled – preventive work on inspection and checking of the state of technical means as part of the system

● Finding and troubleshooting in case of equipment failure

● Repair and replacement of faulty technical equipment

● Modernization and changes in software

MODERNIZATION

In hardware and software, the introduction of new technologies, the transition to more universal platforms of automation systems, which allow the full use of achievements in the field of information transmission, processing and storage, is taking place quite quickly.

Unfortunately, a significant amount of existing hardware that has already been discontinued is not supported by the manufacturer’s service. «CSC – Automation» provides updates of the software and hardware parts of enterprise automation systems to new versions of software and hardware. This makes it possible to extend the service life of technological sites, to switch to a new hardware and software environment with the possibility of using modern functionality.